Zebra ZE500 Manual: A Comprehensive Guide

Today’s date is December 31, 2025, at 19:07:55 (). This manual details the Zebra ZE500 printer, covering orientation, troubleshooting, and operational aspects. Explore guides from manualsdir.ru and mungfali.com for detailed insights.

The Zebra ZE500 series represents a robust and versatile line of industrial printers, designed for demanding labeling applications across diverse sectors. These printers excel in environments requiring high-volume, durable labels – from manufacturing and logistics to healthcare and retail. The ZE500 is engineered to enhance operational efficiency and accuracy, offering a blend of speed, reliability, and user-friendliness.

This manual serves as a comprehensive resource for understanding and operating your Zebra ZE500 printer. It covers everything from initial setup and media handling to advanced configuration and troubleshooting. Whether you’re a seasoned professional or new to thermal printing, this guide will equip you with the knowledge to maximize your printer’s potential.

Key features of the ZE500 include its adaptable design, supporting both direct thermal and thermal transfer printing methods. This flexibility allows for cost-effective label production based on specific application needs. Furthermore, the printer’s intuitive control panel and connectivity options – including Ethernet and wireless capabilities – streamline integration into existing workflows. Resources like those found on manualsdir.ru provide supplementary information regarding printer orientation and overall functionality, aiding in a smoother user experience.

Unboxing and Initial Setup

Upon receiving your Zebra ZE500 printer, carefully inspect the packaging for any signs of damage during transit. Once confirmed, open the box and verify that all components are present. These typically include the printer itself, a power cord, a USB cable, a quick start guide, and potentially a sample roll of media and ribbon, depending on the configuration.

Begin by placing the printer on a stable, level surface with adequate ventilation. Connect the power cord to the printer and a grounded electrical outlet. Avoid using extension cords if possible. Next, connect the USB cable to the printer and your computer – this is for initial configuration and driver installation. Do not power on the printer yet.

Refer to the quick start guide for initial media loading instructions. Ensure the media is correctly threaded through the printer’s path. Before powering on, double-check all connections. Powering on the printer initiates a self-test, which verifies basic functionality. Consult resources like manualsdir.ru for visual guidance on printer orientation during setup, ensuring proper alignment and operation. Following these steps ensures a smooth and trouble-free initial setup process.

Printer Specifications and Features

The Zebra ZE500 series represents a robust line of industrial printers designed for demanding labeling applications. Key specifications include a 4-inch print width, supporting a variety of label materials and thicknesses. It boasts a print resolution ranging from 203 to 300 dpi, ensuring crisp, clear images and text.

Connectivity options are comprehensive, encompassing USB, Ethernet (including 10/100 Ethernet), and optional wireless capabilities. The printer supports various one-dimensional and two-dimensional barcodes, alongside diverse fonts and graphics. Its durable construction ensures reliable performance in challenging environments.

Notable features include user-friendly media handling, accommodating different media roll sizes and types. The ZE500 also offers real-time clock (RTC) functionality for accurate date and time stamping on labels. Advanced features, detailed in resources like manualsdir.ru, include customizable label formats and integration with various printing languages (ZPL and EPL). The printer’s compact design optimizes workspace utilization, while its high-speed processing delivers efficient label production. It’s a versatile solution for diverse industrial needs.

Understanding the Control Panel

The Zebra ZE500 control panel provides a user-friendly interface for managing printer functions and monitoring status. Typically, it features a series of illuminated buttons and a display screen, offering intuitive control over printer operations. Common buttons include ‘Pause,’ ‘Stop,’ ‘Feed,’ and ‘Online/Offline’ for immediate control.

The display screen presents vital information such as printer status (ready, paused, error), media levels, ribbon status, and error messages. Navigating the menu system, accessible through dedicated buttons, allows users to adjust printer settings, calibrate the media sensor, and perform self-tests.

Understanding the LED indicators is crucial; these signal various conditions like power status, communication activity, and error alerts. Referencing the Zebra ZE500 manual (available on resources like manualsdir.ru) provides a detailed explanation of each indicator’s meaning. The control panel facilitates basic troubleshooting, enabling users to address common issues without requiring a computer connection. Mastering the control panel streamlines operation and minimizes downtime, ensuring efficient label production.

Media Loading and Calibration

Proper media loading is fundamental for successful printing with the Zebra ZE500. Begin by ensuring the platen roller is clean and free of debris. Carefully unroll the labels, aligning them with the media path and securing the roll onto the spindle. The media guides must be adjusted to firmly, but not tightly, hold the labels in place, preventing skewing during printing.

Calibration is essential after loading new media or if print quality is inconsistent. Access the calibration function through the control panel menu. The printer will automatically detect the label’s gaps or marks, establishing accurate print positioning. Following the on-screen prompts ensures precise calibration.

Refer to the Zebra ZE500 manual (found on resources like manualsdir.ru) for specific instructions tailored to your label type – die-cut, continuous, or notched. Incorrect calibration leads to misaligned prints, wasted labels, and potential printer errors. Regularly check media levels and replace rolls promptly to maintain uninterrupted operation. Proper loading and calibration are key to optimal print quality and efficiency.

Ribbon Installation and Replacement

Installing and replacing the ribbon in your Zebra ZE500 is a straightforward process, crucial for thermal transfer printing. First, ensure the printer is powered off. Open the ribbon compartment, typically located on the top or side of the printer. Carefully unroll a small portion of the ribbon and align it with the ribbon spindle, securing it in place.

The ribbon must be threaded correctly through the platen roller and printhead. Consult the Zebra ZE500 manual (available on manualsdir.ru) for a detailed diagram illustrating the correct path. Ensure the ribbon’s coated side faces the labels during printing. Improper threading can lead to poor print quality or ribbon jams.

When replacing a used ribbon, always dispose of the old ribbon responsibly. Before installing a new ribbon, inspect the printhead for any debris or residue. Regularly cleaning the printhead extends its lifespan and maintains optimal print quality. Proper ribbon installation and timely replacement are vital for consistent, high-quality thermal transfer printing with your Zebra ZE500.

Printhead Maintenance and Cleaning

Maintaining a clean printhead is paramount for optimal Zebra ZE500 performance and print quality. Dust, debris, and adhesive residue can accumulate, causing streaks, faded characters, or even complete print failure. Regular cleaning, ideally after every ribbon roll change, prevents these issues.

Recommended Cleaning Procedure: Power off the printer and allow the printhead to cool. Gently open the printer and locate the printhead. Use a lint-free cloth dampened with isopropyl alcohol (90% or higher) to carefully wipe the entire surface of the printhead. Avoid abrasive materials that could damage the delicate heating elements.

For stubborn residue, specialized printhead cleaning pens are available. These pens offer a more targeted cleaning solution. Always follow the manufacturer’s instructions when using cleaning pens or solutions. Refer to resources like manualsdir.ru for visual guides. Consistent printhead maintenance extends the printhead’s lifespan and ensures consistently high-quality prints from your Zebra ZE500 printer, minimizing downtime and maximizing efficiency.

Basic Printer Operation: Direct Thermal vs. Thermal Transfer

The Zebra ZE500 supports two primary printing methods: Direct Thermal and Thermal Transfer. Understanding the difference is crucial for selecting the correct media and achieving desired results. Direct Thermal printing uses heat-sensitive media, creating an image directly on the label without the need for ribbon. This method is ideal for short-life applications like shipping labels or receipts, where durability isn’t a primary concern.

Thermal Transfer printing, conversely, utilizes a ribbon coated with wax or resin-based ink. Heat from the printhead melts the ink onto the label, creating a permanent, durable image. This is best suited for labels requiring resistance to abrasion, chemicals, or extreme temperatures – think asset tags or product identification labels.

The ZE500 automatically detects the media type, but proper configuration is essential. Selecting the incorrect method will result in poor print quality or a non-functional label. Resources like manualsdir.ru can provide detailed guidance on media selection and printer settings for both printing modes, ensuring optimal performance from your Zebra ZE500.

Connecting the Zebra ZE500 to a Computer

Establishing a connection between your Zebra ZE500 and a computer is a fundamental step for label printing. The ZE500 offers several connectivity options, including USB, Ethernet, and potentially wireless networking depending on the model. USB connection is the simplest, functioning much like a standard plug-and-play device. Simply connect the USB cable from the printer to an available port on your computer.

Ethernet connectivity allows for network-wide access to the printer. This requires connecting the ZE500 to your network via an Ethernet cable and configuring its IP address. Wireless configuration, if available, involves connecting to your Wi-Fi network through the printer’s control panel or web interface.

Once physically connected, you’ll need to install the appropriate drivers (covered in the next section). Resources like manualsdir.ru offer detailed instructions for each connection type, including troubleshooting common connectivity issues. Proper connection ensures seamless communication and efficient label printing from your computer to the Zebra ZE500.

Driver Installation and Configuration

After physically connecting your Zebra ZE500 to your computer, installing the correct drivers is crucial for proper functionality. Drivers act as a translator, enabling communication between the printer and your operating system. You can typically download the latest drivers from the Zebra Technologies website or utilize the installation disc included with your printer (if provided).

During installation, follow the on-screen prompts carefully. The installer will guide you through selecting the correct printer model and connection type (USB, Ethernet, or Wireless). Once installed, you may need to configure printer settings through the operating system’s control panel. This includes setting the default paper size, print quality, and other preferences.

Resources like manualsdir.ru can provide step-by-step instructions and troubleshooting tips for driver installation. Ensure the driver version is compatible with your operating system for optimal performance. Correct driver installation and configuration are essential for reliable label printing and avoiding common communication errors.

Label Design Software Overview

To create and customize labels for your Zebra ZE500, you’ll need label design software. Zebra offers its own software solutions, such as ZebraDesigner, but numerous third-party options are also compatible. These programs provide a user-friendly interface for designing labels with text, barcodes, images, and other elements.

Most label design software features a drag-and-drop interface, allowing you to easily position elements on the label template. You can import data from various sources, like spreadsheets or databases, to dynamically populate labels with variable information. Key features include barcode generation, text formatting, and image insertion.

Understanding the software’s tools for setting label dimensions, margins, and print resolution is vital. Resources like online tutorials and documentation (potentially found on sites like manualsdir.ru) can assist with mastering the software’s capabilities. Proper label design ensures accurate and professional-looking prints from your Zebra ZE500 printer.

Printing Your First Label

After installing the drivers and designing your label, printing your first label with the Zebra ZE500 is a straightforward process. Ensure the printer is powered on and connected to your computer, either via USB, Ethernet, or wirelessly, as configured during setup. Open your label design software and load the designed label template.

Verify that the correct printer (Zebra ZE500) is selected within the software’s print settings. Adjust print quantity as needed. Before initiating the print job, double-check the media path – that labels are correctly loaded and the ribbon (if using thermal transfer) is properly installed. A test print is highly recommended.

Initiate the print command from the software. Observe the printer to confirm it’s feeding the label stock and applying the print. If issues arise, consult the troubleshooting section of this manual or resources like those found on manualsdir.ru. Successful printing confirms proper configuration and operation of your Zebra ZE500.

Troubleshooting Common Printing Issues

Encountering issues with your Zebra ZE500? Several common problems have readily available solutions. Poor print quality often stems from a dirty printhead; regular cleaning (see Printhead Maintenance) is crucial. Label jams can occur due to improper media loading or debris in the path – ensure correct alignment and inspect for obstructions.

If the printer isn’t recognized by your computer, verify cable connections (USB/Ethernet) and driver installation. Check network settings for wireless connections. Smudged or faded prints usually indicate ribbon issues (incorrect type, worn ribbon, or improper tension). Ensure the ribbon matches your label material.

Error messages (refer to the Error Messages and Codes Explained section) provide valuable clues. Resources like mavink.com offer troubleshooting guides. If problems persist, consult the Zebra support website or the manual available on manualsdir.ru. Regularly performing preventative maintenance minimizes these common issues, ensuring consistent performance from your ZE500.

Error Messages and Codes Explained

The Zebra ZE500 utilizes a comprehensive system of error messages and codes to diagnose issues. These messages, displayed on the control panel or within the printer’s software, pinpoint the source of the problem, enabling efficient troubleshooting. “Media Out” indicates the label supply is depleted or incorrectly loaded. “Ribbon Out” signifies a depleted or improperly installed ribbon.

“Printhead Overheat” suggests excessive printing without adequate cooling; reduce print speed or allow the printhead to cool. “Communication Error” points to connectivity problems between the printer and the host computer or network. Verify cable connections and network settings.

More complex codes, often numerical, require referencing the official Zebra documentation (available on manualsdir.ru). These codes detail specific hardware or software malfunctions. Understanding these messages is vital for resolving issues quickly. Ignoring error codes can lead to further damage or reduced printer performance. Regularly checking for firmware updates can also address known error conditions and improve overall system stability.

Network Configuration (Ethernet/Wireless)

The Zebra ZE500 supports both Ethernet and wireless network connectivity, enabling centralized printer management and remote operation. Ethernet configuration involves connecting the printer to your network via an RJ45 cable and assigning a static IP address or utilizing DHCP for automatic assignment. Access the printer’s web interface (using the assigned IP address) to configure network settings.

Wireless setup requires selecting your network SSID and entering the correct password. Ensure your wireless network is secure and compatible with the printer’s supported protocols (802.11 a/b/g/n). After connecting, verify network connectivity by printing a network configuration page directly from the printer’s control panel.

Proper network configuration allows for seamless integration with your existing infrastructure. Refer to the Zebra documentation (found on resources like manualsdir.ru) for detailed instructions and troubleshooting tips. Incorrect network settings can lead to communication errors and printing failures. Regularly check network connectivity to ensure optimal performance.

Firmware Updates and Management

Maintaining up-to-date firmware on your Zebra ZE500 is crucial for optimal performance, security, and compatibility with new features. Zebra regularly releases firmware updates to address bugs, enhance functionality, and improve overall system stability. Firmware updates can be applied via several methods, including USB, Ethernet, or wirelessly, depending on your network configuration.

To update the firmware, download the latest version from the official Zebra website. Follow the provided instructions carefully, ensuring the printer remains powered on throughout the process. Interrupting the update can potentially damage the printer’s internal systems. The web interface, accessible through the printer’s IP address, often provides a firmware update utility.

Firmware management also includes monitoring the current version installed and establishing a schedule for regular checks. Utilizing Zebra’s printer management software can automate this process across multiple printers. Resources like manualsdir.ru offer guidance on locating and installing firmware updates. Always back up your printer configuration before performing a firmware update.

Cleaning and Preventative Maintenance

Regular cleaning and preventative maintenance are essential for extending the lifespan and ensuring the reliable operation of your Zebra ZE500 printer. Dust, label residue, and debris can accumulate, leading to print quality issues and potential hardware failures. A consistent cleaning schedule minimizes these risks.

Daily cleaning should include wiping down the exterior surfaces with a soft, lint-free cloth. Weekly maintenance involves cleaning the printhead with a specialized printhead cleaning pen or card, removing any accumulated residue. Avoid abrasive cleaners, as they can damage the printhead. The platen roller should also be inspected and cleaned to maintain proper label feeding.

Monthly preventative measures include a thorough inspection of all components, checking for wear and tear. Lubricate moving parts as recommended in the Zebra ZE500 manual. Resources like manualsdir.ru provide detailed cleaning instructions. Proper maintenance not only improves print quality but also reduces the likelihood of costly repairs and downtime, ensuring consistent performance.

Replacing Consumable Parts (Platen Roller, Cutter)

The Zebra ZE500, like all thermal printers, requires periodic replacement of consumable parts to maintain optimal performance. The platen roller, responsible for feeding labels, wears down over time, leading to slippage or inconsistent printing. Replacement is necessary when labels no longer feed correctly or exhibit distorted prints.

The cutter, used to separate labels after printing, also has a limited lifespan. Signs of a failing cutter include ragged edges, incomplete cuts, or the cutter jamming. Replacing the cutter restores clean and efficient label separation.

Refer to the official Zebra ZE500 manual for detailed instructions and part numbers. Replacement procedures typically involve removing a few screws and carefully installing the new component. Ensure the printer is powered off before attempting any repairs. Resources like manualsdir.ru can offer visual guides. Using genuine Zebra replacement parts guarantees compatibility and maintains the printer’s warranty. Regular inspection and timely replacement of these parts prevent downtime and ensure consistent label output.

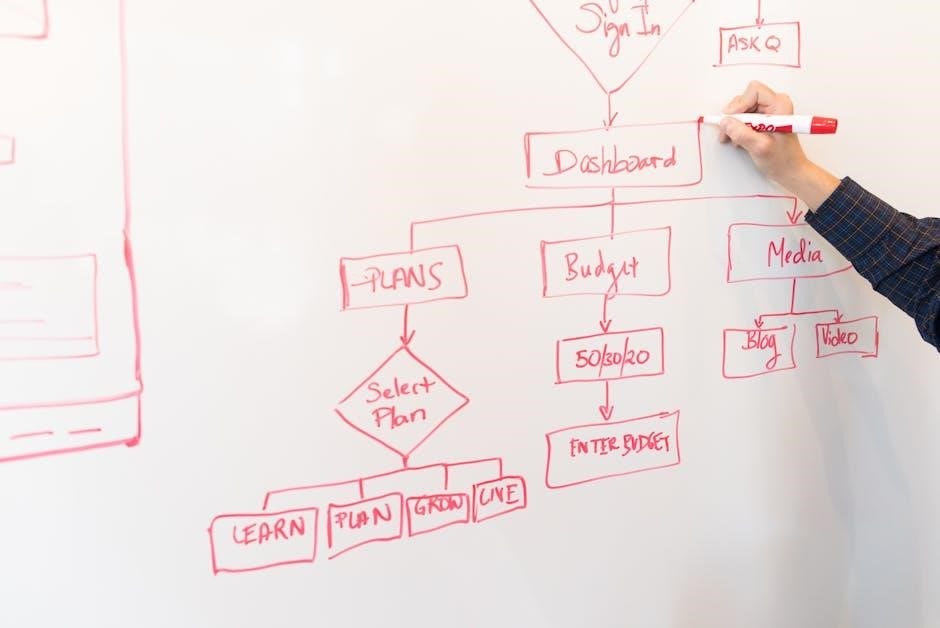

Understanding Printer Orientation Settings

The Zebra ZE500 offers configurable printer orientation settings crucial for accurate label application. These settings dictate how the printed image is rotated relative to the label feed direction. Understanding these options is vital for ensuring labels are printed correctly, aligning with the intended placement on products or packaging.

Common orientation options include Normal (standard orientation), 90 degrees, 180 degrees, and 270 degrees rotation. The correct setting depends on the label design and how the printer is physically positioned within your workflow. Incorrect orientation can result in labels being printed upside down or sideways.

These settings are typically adjusted through the printer’s control panel or via the printer driver on a connected computer. Consult the Zebra ZE500 manual (available on resources like manualsdir.ru) for specific instructions. Experimentation may be needed to determine the optimal setting for your application. Proper orientation ensures readability and professional-looking label presentation, contributing to efficient operations and a positive brand image.

Advanced Settings and Customization

The Zebra ZE500 provides a range of advanced settings for tailoring printer performance to specific needs. These customizations extend beyond basic operation, allowing users to fine-tune print quality, connectivity, and overall functionality. Exploring these options unlocks the printer’s full potential.

Key areas for advanced configuration include media type selection (direct thermal, thermal transfer), darkness settings for optimal print contrast, and speed adjustments to balance print quality and throughput. Network settings, crucial for Ethernet or wireless connectivity, allow for seamless integration into existing infrastructure.

Furthermore, the ZE500 supports custom label formats and programming languages, enabling complex label designs and data integration. Refer to the comprehensive Zebra ZE500 manual (found on resources like manualsdir.ru) for detailed guidance on utilizing these features. Troubleshooting guides, such as those available on mavink.com, can assist in resolving any configuration challenges. Mastering these advanced settings ensures the ZE500 operates at peak efficiency and meets unique labeling requirements.

Safety Precautions and Warnings

Important safety guidelines must be followed when operating the Zebra ZE500 printer to prevent injury and ensure reliable performance. Always disconnect the power cord before performing any maintenance or troubleshooting procedures. Avoid touching the printhead immediately after printing, as it reaches high temperatures and can cause burns.

Never operate the printer in wet or humid environments, as this poses an electrical hazard. Ensure adequate ventilation around the printer to prevent overheating. Do not attempt to disassemble or modify the printer beyond the procedures outlined in the official Zebra ZE500 manual (available on resources like manualsdir.ru).

Use only approved accessories and consumables, as using incompatible parts can damage the printer and void the warranty. Be cautious when handling ribbons and labels, avoiding sharp edges. Regularly inspect the power cord for damage and replace it if necessary. Refer to troubleshooting resources, such as those found on mavink.com, for guidance on addressing potential safety concerns. Prioritizing safety ensures a long and productive lifespan for your Zebra ZE500.